An Overview of HSG 48: Updated 2025

HSG48 is official guidance from the Health and Safety Executive (HSE) aimed at managers, health and safety professionals, and employee safety representatives. First published in 1989 and revised in 1999, it addresses the role of human factors in health and safety and provides practical ways to reduce errors and influence behaviour positively.

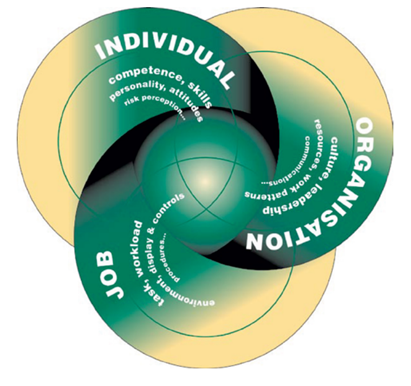

Human factors encompass environmental, organisational, and job-specific aspects, as well as individual characteristics that can influence behaviour at work and affect health and safety outcomes. HSG48 focuses on recognising, assessing, and managing these human factors to reduce workplace accidents and improve safety culture.

While technical systems have become increasingly reliable, research shows that up to 80% of workplace accidents involve human factors. Understanding these influences and implementing measures to reduce them is key to an effective safety management system.

© Nopsema.org

The HSG48 guidance looks specifically at behavioural safety. This can include the behaviour of individuals within the organisation but also the company’s attitude to behaviour as a whole.

What is behavioural safety?

Behavioural safety focuses on the actions, decisions, and attitudes of individuals in the workplace and how these can be optimised for improved health and safety outcomes. HSG48 provides structured guidance on how organisations can manage behavioural safety more effectively.

It addresses both individual behaviour and the organisation’s overall attitude towards safety, recognising that cultural and managerial approaches can significantly influence employee behaviour.

Click here to download an illustrated diagram of human error

What are the key sections of HSG 48?

Chapter 1: What are human factors?

The HSE defines human factors as environmental, organisational, and job factors, along with human and individual characteristics, that influence behaviour at work in ways that can affect health and safety.

These are grouped into three core areas:

-

The job – Designing tasks in line with ergonomic principles to match human capabilities and avoid overload.

-

The individual – Recognising that skills, attitudes, habits, and personal attributes can be strengths or weaknesses depending on the task.

-

The organisation – Developing a positive safety culture that engages employees at all levels and promotes compliance with safety standards.

HSG48 also highlights that telling workers to “take more care” is not a sufficient control measure. For example, in one case study, a worker was crushed by reversing machinery where simple design changes and footwear checks could have prevented the incident.

Chapter 2: Understanding human failure

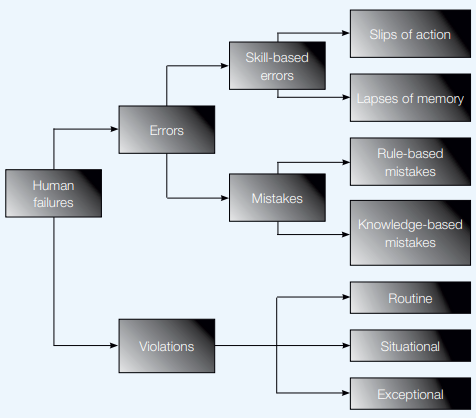

HSG48 distinguishes between errors and violations:

-

Errors are unintended actions or decisions, including slips (actions not as planned), lapses (memory failures), and mistakes (wrong actions believed to be correct).

-

Violations are deliberate deviations from rules or procedures, which may be routine, situational, or exceptional.

The guidance also explains active failures (immediate impact, often by front-line staff) and latent failures (hidden organisational or design flaws that can lie dormant until triggered).

Major accident case studies such as Piper Alpha and Clapham Junction illustrate how human and organisational failures often combine with technical faults to cause disasters.

Chapter 3: Designing for people

This chapter covers the importance of ergonomic and job design in preventing human error. Topics include:

-

Designing controls and displays for ease of use and error prevention.

-

Adapting workstations to suit different physical sizes and capabilities.

-

Considering mental well-being by designing jobs that balance workload, variety, autonomy, and social interaction.

-

Addressing workplace stressors such as excessive noise, poor lighting, or unclear roles.

Job design improvements such as job rotation, horizontal enlargement, and increasing autonomy can enhance both safety and satisfaction.

Chapter 4: Managing influences on human performance

Key influences on performance include fatigue, shift patterns, communication during shift changes, and the overall health and safety culture of the organisation.

Practical measures include:

-

Reducing fatigue by managing shift length and workload.

-

Standardising communication protocols at shift handovers.

-

Promoting positive attitudes to safety through visible leadership commitment.

Chapter 5: Getting started

HSG48 recommends starting with four key areas:

-

Integrating human factors into risk assessments.

-

Analysing accidents and near misses for human factor causes.

-

Applying human factors thinking in design and procurement decisions.

-

Embedding human factors considerations into day-to-day operations.

The guidance includes a workplace checklist that can help identify problem areas and prioritise action.

Chapter 6: Case studies

Real-world examples in HSG48 show how organisations in industries such as manufacturing, petrochemicals, and transport have tackled human factor issues. These range from low-cost equipment modifications to changes in supervision and training.

Summarising these case studies within your own article can help readers relate the guidance to their own industry.

Using HSG48 in your organisation

Even though HSG48 was last updated in 1999, its principles remain highly relevant. Many organisations now incorporate behavioural safety into risk management, using the guidance to:

-

Understand the types and causes of human failure.

-

Identify organisational, job, and individual factors affecting safety.

-

Implement practical, often low-cost, measures to reduce risk.

Useful resources on HSG 48

Here we have linked some of the links that those wishing to learn more about HSG48 may find useful:

Human factors in behavioural safety: https://www.hse.gov.uk/humanfactors/topics/behaviouralintor.htm

Managing human failure: https://www.hse.gov.uk/humanfactors/topics/humanfail.htm

Human failure: aid memoir: https://www.hse.gov.uk/humanfactors/topics/types.pdf